Aluminium Sheets/Plates, Coils Suppliers in Dahod– Alloy 6061, 6082, 5052, 1100, 1050, HE 20, HE 30 in T6 and T651 Tempers, ASTM B209, ASTM-B-209, EN573, EN485

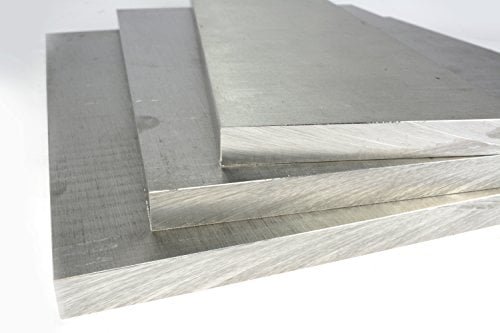

Aluminium sheet is the most widely used form of Industrial Aluminium. Aluminium sheets and plates find applications in various industries such as manufacturing cans and packages, transportation, home appliances, building and construction. An ISO 9001:2008 Certified Company, Metline Industries (Steel Plates & Coil Division) is one of the most trusted distributor and supplier of Aluminium sheets and plates in Dahod, Gujarat and worldwide. We can offer Aluminium sheets in a wide range of grades and tempers including various commercial and special alloys such as 1100, 1050, 1200, 2014, 2024, 3003, 5052, 5083, 5086, 6061, 6082, 7075, 8011, 19500. All products offered by Metline Industries, comply with the technical specifications of International Standards – ASTM-B-209M, EN573, EN485.

In Dahod, Metline is one of the biggest supplier of Aluminium sheets in grade 6061, 6082, 5052, 1100, HE 20, HE 30 in T6 and T651 Tempers manufactured in accordance with international standards ASTM B209, ASTM-B-209, EN573, and EN485.

- Increased Strength

- Good Corrosion Resistance

- Higher Machinability

- Ease of Welding

Aluminium sheets are available in a thickness range of 0.5mm up to 5mm. The general widths of Aluminum sheets are 1000mm, 1250mm and 1500mm, while common lengths are 2000mm, 2500 mm and 3000mm respectively.

| Aluminium Sheets Product Range |

| Alloy No. | Thickness

(mm) | Width

(mm) | Length

(mm) | Temper |

| A1050, A1060, A1070, A1100 | 0.2-5.0 | 20-2200 | 20-8000 | O, H12, H22, H14, H16, H18, H24, H26 |

| A3003, A3105, A3004 | 0.2-5.0 | 20-2200 | 20-8000 | O, H14, H18, H24 |

| A5052, A5005, A5083, A5086, A5754 | 0.2-5.0 | 20-2200 | 20-8000 | O, H18, H24, H32, H34, H111, H112 |

| A6061, A6082, A6063 | 0.2-5.0 | 20-2200 | 20-8000 | T4, T6, T651 |

| A8011 | 0.2-5.0 | 20-2200 | 20-8000 | O, H12, H22, H14, H16, H18, H24, H26 |

Specifications for Aluminium Plates, Sheets, Coil Products – Product Grades

European

Standard | BS (OLD) | USA (AA) | GERMANY

(DIN) | ISO | IS | Canadian |

| EN AW-1050 A | 1E | 1050 | Al99.5 | Al99.5 | 19500, 19501 | 1 S |

| EN AW-1070 A | – | 1070 | Al-99.7 | Al-99.7 | 19700 | – |

| EN AW-1100 | IC | 1100 | Al-99.0 | Al-99.0 | 19000 | 2 S |

| EN AW-2011 | FC1 | 2011 | AlCuBiPb | AlCu6BiPb | – | 28S |

| EN AW-2014 | HE15 | 2014 | AlCuSiMn | AlCu4SiMg | 24345 | B26S |

| EN AW-2024 | – | 2024 | AlCuMg2 | AlCu4Mg1 | – | 24 S |

| EN AW-3003 | N3 | 3003 | AlMnCu | AlMn1Cu | 31000 | 3 S |

| EN AW-3103 | – | 3103 | – | AlMn1 | – | – |

| EN AW-6101A | E91E | 6101 | E AlMgSi 0.5 | E AlMgSi(A) | 63401 | D50S |

| EN AW-6005 | – | 6005 | AlMgSi0.7 | AlSiMg | 62400 | C51S |

| EN AW-6351 | HE30 | 6351 | AlMgSi1 | AlSiMg0.5Mn | 64430 | B51S |

| EN AW-6060 | – | 6060 | AlMgSi 0.5 | AlMgSi | – | – |

| EN AW-6061 | HE20 | 6061 | AlMgSiCu | AlMg1SiCu | 65032 | 65S |

| EN AW-6063 | HE9 | 6063 | AlMgSi0.5 | AlMg0.7Si | 63400 | 50S |

| EN AW-6082 | HE30 | 6351 | AlMgSi1 | AlSi1MgMn | 64430 | B51S |

Specifications for Aluminium Plates, Sheets, Coil Products – Chemical Composition

| Alloy | %

Si | %

Mg | %

Mn | %

Cu | %

Fe | %

Cr | %

Zn | %

Ti | %

Others | %

Al |

| EN AW-1050 A | 0.25

Max | 0.05

Max | 0.05

Max | 0.05

Max | 0.40

Max | – | 0.07

Max | 0.05

Max | – | 99.5 Min |

| EN AW-1070 A | 0.20

Max | 0.03

Max | 0.03

Max | 0.03

Max | 0.25

Max | – | 0.07

Max | 0.03

Max | – | 99.7 Min |

| EN AW-1100 | Si+Fe 0.95 Max | – | 0.05 Max | 0.05 – 0.20 | – | – | 0.10 Max | 0.05 Max | – | 99.0 Min |

| EN AW-2011 | 0.40 Max | – | – | 5.00 – 6.00 | 0.70 Max | – | 0.30 Max | – | Bi : 0.20 – 0.60

Pb : 0.20 – 0.60 | Remainder |

| EN AW-2014 | 0.50 – 1.20 | 0.20 – 0.80 | 0.40 – 1.20 | 3.90 – 5.00 | 0.70 Max | 0.10 Max | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-2024 | 0.50 Max | 1.20 -1.80 | 0.30 – 0.90 | 3.80 – 4.90 | 0.50 Max | 0.10 Max | 0.25 Max | 0.15 Max | 0.15 Max | Remainder |

| EN AW-3003 | 0.60 Max | – | 1.00 – 1.50 | 0.05 – 0.20 | 0.70 Max | – | 0.10 Max | – | 0.15 Max | Remainder |

| EN AW-3103 | 0.50 Max | 0.30 Max | 0.90 – 1.50 | 0.10 Max | 0.70 Max | 0.10 Max | 0.20 Max | 0.10 Max | – | Remainder |

| EN AW-6101A | 0.30 – 0.7 | 0.40 – 0.90 | 0.03 Max | 0.05 Max | 0.40 Max | – | – | – | 0.10 Max | Remainder |

| EN AW-6005 | 0.60 – 0.90 | 0.40 – 0.60 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6351 | 0.70 – 1.30 | 0.40 – 0.80 | 0.40 – 0.80 | 0.10 Max | 0.50 Max | – | 0.20 Max | 0.20 Max | 0.15 Max | Remainder |

| EN AW-6060 | 0.30 – 0.60 | 0.35 – 0.60 | 0.10 Max | 0.10 Max | 0.10 – 0.30 | 0.05 Max | 0.15 Max | 0.10 Max | – | Remainder |

| EN AW-6061 | 0.40 – 0.80 | 0.80 – 1.20 | 0.15 Max | 0.15 – 0.40 | 0.70 Max | 0.04 – 0.35 | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-6063 | 0.20 – 0.60 | 0.45 – 0.90 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6082 | 0.70 – 1.30 | 0.60 -1.20 | 0.40 – 1.00 | 0.10 Max | 0.50 Max | 0.25 Max | 0.20 Max | 0.10 Max | – | Remainder |

Specifications for Aluminium Plates, Sheets, Coil Products – Mechanical Properties

| Alloy | Temper | UTS (Mpa) | Yield Strength (Mpa) | Elongation (%) |

| Minimum | Maximum | Minimum | Maximum | A 50mm (Minimum) |

| EN AW-1050 A | F | 60 | – | 20 | – | 23 |

| O | 60 | 95 | 20 | – | 23 |

| EN AW-1070 A | F | 60 | – | 20 | – | 23 |

| EN AW-1100 | O | 75 | 110 | – | – | 25 |

| EN AW-2011 | T4 | 275 | – | 125 | – | 12 |

| T6 | 310 | – | 230 | – | 6 |

| EN AW-2014 | O | – | 250 | – | 135 | 10 |

| T4 | 370 | – | 230 | – | 11 |

| T6 | 415 | – | 370 | – | 5 |

| EN AW-2024 | O | – | 250 | – | 150 | 10 |

| T3,T3510,T3511 | 395 | – | 290 | – | 6 |

| T8,T8510,T8511 | 455 | – | 380 | – | 4 |

| EN AW-3003 | F | 95 | – | 35 | – | 20 |

| O | 95 | 135 | 35 | – | 20 |

| EN AW-3103 | F | 95 | – | 35 | – | 20 |

| O | 95 | 135 | 35 | – | 20 |

| EN AW-6101A | T6 | 200 | – | 170 | – | 8 |

| EN AW-6005 | T4 | 180 | – | 90 | – | 13 |

| T6 | 270 | – | 225 | – | 6 |

| EN AW-6351 | O | – | 160 | – | 110 | 12 |

| T4 | 205 | – | 110 | – | 12 |

| T6 | 290 | – | 250 | – | 6 |

| EN AW-6060 | T4 | 120 | – | 60 | 14 | 12 |

| T5 | 160 | – | 120 | – | 6 |

| T6 | 190 | – | 150 | – | 6 |

| T64 | 180 | – | 120 | – | 10 |

| T66 | 215 | – | 160 | – | 6 |

| EN AW-6061 | O | – | 150 | – | 110 | 14 |

| T4 | 180 | – | 110 | – | 13 |

| T6 | 260 | – | 240 | – | 6 |

| EN AW-6063 | O | – | 130 | – | – | 16 |

| T4 | 130 | – | 65 | – | 12 |

| T5 | 175 | – | 130 | – | 6 |

| T6 | 215 | – | 170 | – | 6 |

| T66 | 245 | – | 200 | – | 6 |

| EN AW-6082 | O | – | 160 | – | 110 | 12 |

| T4 | 205 | – | 110 | – | 12 |

| T5 | 270 | – | 230 | – | 6 |

| T6 | 290 | – | 250 | – | 6 |

Reviews

There are no reviews yet.