AA5754 is one of the most widely used aluminium alloys. 5754 aluminum is an alloy of aluminum, further classified within the AA 5000 series (aluminum-magnesium wrought alloy). 5754 is the Aluminum Association (AA) designation for this material. In European standards, it will typically be given as EN AW-5754. AlMg3 is the EN chemical designation. And A95754 is the UNS number.

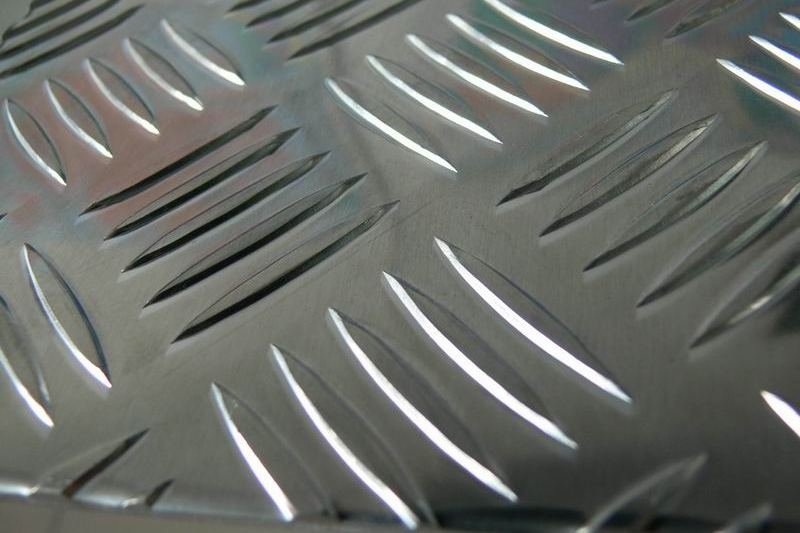

Aluminium 5754 sheets and plates exhibit greater corrosion resistance in both seawater corrosion and industrially polluted atmospheres, and is widely used for applications in marine, oil, & gas, chemical and nuclear industry.

5754 aluminium alloy is an alloy in the wrought aluminium -magnesium family (5000 or 5xxx series). It is closely related to the alloys 5154 and 5454 (Aluminum Association designations that only differ in the second digit are variations on the same alloy). Of the three 5×54 alloys, 5754 is the least alloyed (highest composition % of aluminium), but only by a small amount. It is used in similar applications. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility.

What are the Various Tempers in with Aluminium 5754 Plates Can be Supplied?

The most common tempers for 5754 aluminium plates are shown below with H111, H22 being the most common tempers used:

- O – Soft

- H111 – Some work hardening imparted by shaping processes but less than required for H11 temper

- H22 – Work hardened by rolling then annealed to quarter hard

- H24 – Work hardened by rolling then annealed to half hard

- H26 – Work hardened by rolling then annealed to three-quarter hard

- H114

Chemical Composition of 5754 Aluminium Sheets, Plates, Coils

The alloy composition of 5754 aluminium is:

- Aluminium: 94.2 to 97.4%

- Chromium: 0.3% max

- Copper: 0.1% max

- Iron: 0.4% max

- Magnesium: 2.6 to 3.6%

- Manganese: 0.5% max

- Silicon: 0.4% max

- Titanium: 0.15% max

- Zinc: 0.2% max

- Residuals: 0.15% max

Mechanical Properties of 5754 Aluminium Sheets, Plates, Coils

- Tensile Strength 245 – 290 MPa

- Elongation A50 mm 10 – 15%

- Proof Stress 185 – 245 MPa

- Density 2.66 g/cm³

- Melting Point 600°C

- Modulus of Elasticity 68 GPa

- Thermal Conductivity 147 W/m.K

**The properties above are for 5754 Aluminium Plates in the H22 Condition

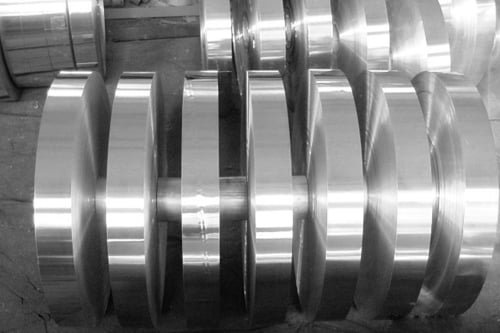

We Specialise in Offering Aluminium Flanges and Profiles Made from 5754 Aluminium Plates

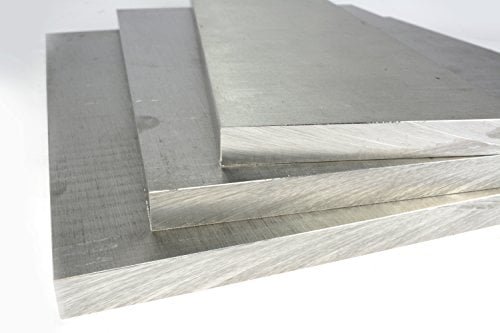

Aluminium 5754 plates are available in a thickness range of 1.0 mm up to 100mm. The general widths of 5754 Aluminum plates are 1000mm, 1250mm, 1500mm, 2000mm while common lengths are 2000mm, 2500 mm and 3000mm respectively. We specialise in offering our customers with custom width and length aluminium 5754 Plates.

Aluminum Products Manufacturing Standards and Data

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- ASTM B210: Standard Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes

- ASTM B211: Standard Specification for Aluminum and Aluminum-Alloy Bar, Rod, and Wire

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B247: Standard Specification for Aluminum and Aluminum-Alloy Die Forgings, Hand Forgings, and Rolled Ring Forgings

- EN 485-2: Aluminium and aluminium alloys. Sheet, strip and plate. Mechanical properties

- EN 573-3: Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 586-2: Aluminium and aluminium alloys. Forgings. Mechanical properties and additional property requirements.

- EN 754-2: Aluminium and aluminium alloys. Cold drawn rod/bar and tube. Mechanical properties

- EN 755-2: Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles. Mechanical properties

- Environmental Degradation of Advanced and Traditional Engineering Materials, Lloyd H. Hihara et al., 2014.

- ISO 6361: Wrought Aluminium and Aluminium Alloy Sheets, Strips and Plates

Reviews

There are no reviews yet.